In China, product procurement is often impacted by the Chinese New Year, a well-recognized challenge in global sourcing. The real turning point lies not in whether these disruptions occur, but in whether they are accounted for in advance as part of the annual planning process.

For international procurement systems, Chinese New Year is not an unexpected event, but a structural milestone that recurs every year, affecting multiple stages across production, materials, and logistics. Without proactive planning, it often turns into a disruption; however, when managed systematically, it becomes a controllable variable within the annual supply chain rhythm.

Based on the ETAs defined in customer contracts, Dihua plans ahead for key stages such as material procurement, production scheduling, and packaging preparation. We also coordinate with upstream and downstream partners to align shutdown and recovery schedules around Chinese New Year, ensuring there is no last-minute scrambling as the holiday approaches. This forward-planning approach allows us to maintain continuity and control over production and shipping during the holiday season.

Not all Chinese holidays have the same impact on supply chains. Holidays such as New Year’s Day, Qingming Festival, Dragon Boat Festival, Mid-Autumn Festival, Labor Day, and National Day typically cause short-term rhythm adjustments — including slower communication, minor production schedule shifts, and tighter shipping windows. With early supply chain planning and execution, these effects can usually be absorbed without disrupting annual delivery plans.

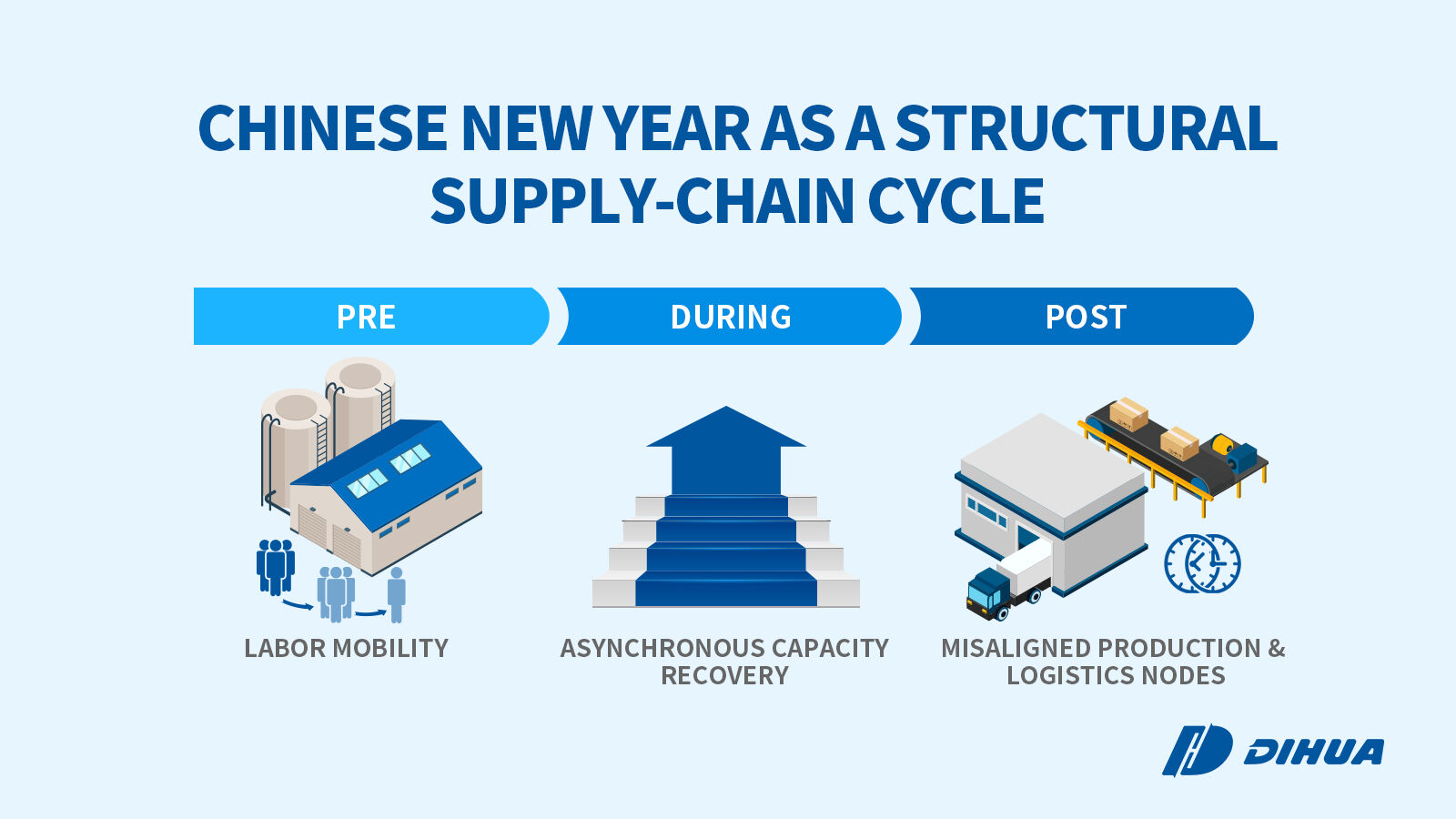

However, Chinese New Year is fundamentally different. It is not just “a few days off,” but a full supply-chain cycle spanning the pre-holiday, during holiday, and post-holiday periods, and is reflected in three key dimensions:

· Structural Labor Mobility

Large-scale worker migration back to hometowns leads to a significant reduction in frontline labor. Production does not follow a simple “stop-and-restart” pattern, but instead enters a gradual wind-down followed by a phased recovery.

· Asynchronous Capacity Recovery

After the holiday, factories, production lines, and workers return at different speeds. Capacity recovers in stages rather than through a synchronized return to full output.

· Misalignment Between Production and Logistics

The overlap of pre-holiday logistics peaks and post-holiday recovery rhythms often creates misalignment between production, warehousing, and shipping, increasing execution complexity.

Because of these structural differences, the impact of Chinese New Year on delivery stability cannot be solved simply by avoiding the holiday period. It must be incorporated as a core variable within annual supply chain planning and execution.

Dihua does not treat Chinese New Year as an unexpected risk, but as a known milestone within our annual supply chain model.

Rather than asking “How should we respond to Chinese New Year?”, we address the key questions in advance:

· Which products must be executed across the holiday period?

· Which execution milestones must be confirmed before the holiday?

· Which steps can be phased over time without affecting delivery stability?

To operationalize this approach, Dihua focuses on four core planning dimensions.

The first structural impact of Chinese New Year is labor and capacity continuity. Dihua identifies and reserves capacity for SKUs that must execute across the holiday period early in the year, preventing key products from being caught in pre-holiday production bottlenecks.

· SKU Prioritization Across the Chinese New Year Period

Key annual SKUs are categorized based on delivery sensitivity — such as launch timelines, promotional calendars, or routine replenishment — ensuring alignment with customers on which products must be delivered during the holiday period.

· Annual Capacity Reservation Mechanism

During production scheduling, capacity is reserved in advance for priority SKUs, avoiding congestion or delays caused by last-minute adjustments.

· Key Material Readiness Planning

Demand and delivery timing for critical materials — including packaging, electronic components, and specialty colorants — are confirmed well ahead of the holiday. This ensures materials align with post-holiday production ramp-up and prevents capacity loss due to material delays.

The impact of Chinese New Year extends across pre-holiday, holiday, and post-holiday execution. Dihua separates critical execution milestones from routine order flow and completes them in advance to reduce uncertainty during the holiday period.

· Milestone Breakdown & Reverse Scheduling

Orders are broken down into key milestones — sample confirmation, packaging approval, testing, production scheduling, final inspection, booking, and shipping — with latest completion dates calculated backward to ensure closure before the holiday begins.

· Pre-Holiday Freeze Points

For orders requiring stability during the holiday, Dihua establishes milestone lock points to finalize confirmations, secure key materials, and complete compliance documentation, minimizing disruption from last-minute changes.

· Cross-Period Planning

For stages that can be phased — such as non-critical replenishment or non-time-sensitive shipments — recovery rhythms and batch schedules are planned in advance to avoid post-holiday backlogs.

During the holiday period, risks related to single-point dependencies are amplified. Dihua mitigates this by designing multi-stage fulfillment structures with flexible execution rhythms.

· Batch Fulfillment Design

Projects are split into multiple manageable batches (by SKU, color, packaging, or market version), maintaining continuous shipping rhythms before, during, and after the holiday.

· Cross-Stage Coordination

Execution is coordinated across production lines, processes, warehousing, and consolidation points to reduce the impact of delays at any single stage.

· Adjustable Rhythm Mechanism

When logistics peaks or post-holiday recovery create pressure, batch priorities and schedules are adjusted to maintain continuity rather than forcing delays.

Holiday-period shipping continuity often depends on whether compliance documentation and testing are completed on time. Missing documents can halt shipments entirely. To avoid this, Dihua integrates compliance planning into the annual execution cycle.

· Pre-Holiday Compliance and Batch Binding

Required compliance documents are completed before the holiday and bound to batch plans, preventing paperwork-related delays.

· Mainstream Market Compliance Coverage

Documentation systems cover key international markets, including EN71, ASTM F963, CPSIA, REACH, and others, ensuring readiness for each customer’s market and channel.

· Standardized Shipping Process

Testing, documentation, labeling, and packing information are integrated into standardized workflows, reducing delays caused by slow communication during the holiday period.

By proactively integrating Chinese New Year into annual supply chain planning and anchoring execution on cross-functional coordination, Dihua transforms this critical period from a temporary risk into a manageable execution variable. Related mechanisms do not rely on one-off responses or single-point fixes. Instead, they are built on long-term planning and system-level coordination, continuously proven to be stable and executable during the Chinese New Year. As a result, delivery schedules remain continuous, predictable, and under control across complex multi-stages.

By integrating Chinese New Year into annual planning and execution coordination, Dihua transforms this period from an unexpected risk into a manageable execution milestone. Even during Chinese New Year, Dihua continues to execute shipments in line with established delivery schedules, allowing projects to progress as planned without holiday-driven postponements.

For international buyers, this shift delivers more than reliable deliveries — it reshapes procurement decision-making:

· Chinese New Year no longer needs to be avoided

· Annual procurement and product launch planning gain greater stability, without being forced into a full reconfiguration due to a single disruption.

· SKU launches and replenishment schedules become more controllable, reducing reactive adjustments caused by holiday disruptions.

· Supply chain risks shift from unpredictable exposure to proactively managed variables

Under this approach, Chinese New Year is better treated as a manageable planning milestone within the annual procurement and supply chain framework, rather than a high-risk period to be deliberately avoided. Based on practical experience, the following practices consistently help improve execution stability during Chinese New Year:

· Consider the full impact of Chinese New Year on manufacturing, logistics, and execution rhythms during the planning stage—not just the official holiday dates.

· Front-load key milestones and priorities within the annual procurement plan, instead of concentrating decisions as the holiday approaches.

· Align delivery rhythms and execution priorities early to reduce uncertainty caused by pre-holiday information gaps.

· Work closely with supply chain partners who bring system-level coordination capabilities and a long-term planning perspective, ensuring that plans remain executable even during complex seasonal periods.

With proactive planning and system coordination, delivery stability during Chinese New Year can be effectively managed. By partnering with supply chain collaborators that offer structured execution, milestone-based planning, and long-term coordination capabilities, holiday-related uncertainties can be absorbed into predictable delivery rhythms. If you are planning for upcoming product cycles or seeking delivery stability during Chinese New Year, visit www.dihuatoys.com to learn more about Dihua’s supply chain capabilities and execution systems. Alternatively, please feel free to contact our team to discuss how proactive planning and systematic execution can help maintain delivery continuity during complex timeframes.

Hot News

Hot News