The global toy supply chain has grown increasingly complex, placing greater pressure on buyers to secure stable delivery, maintain regulatory compliance, and mitigate rising operational risks. With volatile logistics capacity, stricter standards such as EN71, ASTM F963, and CPSIA, and the heightened consequences of stockouts or compliance failures, procurement risk has become a primary challenge for brands, importers, and retailers.

As a result, sourcing decisions have moved beyond price. Buyers now assess a supplier’s ability to deliver reliably, operate transparently, and provide complete compliance assurance. Global procurement teams increasingly prioritize partners with integrated manufacturing and trading capabilities—those able to manage end-to-end execution and support market-ready products.

As stable delivery, compliance assurance, and operational transparency become core procurement benchmarks, Dihua integrates manufacturing and trading resources through its factory–trade model. This approach allows Dihua to reduce sourcing risks for global buyers while maintaining a highly competitive cost structure, achieving an effective balance between risk control and cost optimization.

Over the past three years, logistics disruptions, shipping volatility, and stricter EU and U.S. regulations have significantly reshaped the procurement landscape. Buyers now face three persistent challenges:

· Uncertain delivery timelines, especially during peak seasons, leading to stockouts, lost sales, and missed promotions.

· Non-conforming or delayed compliance documentation, which can hinder customs clearance or prevent marketplace listings.

· Quality and production inconsistencies that increase operational costs by forcing excess safety stock or supplier diversification.

These pressures make one thing clear: a sourcing partner must offer more than manufacturing capability—they must ensure stable supply-chain execution and a robust compliance framework that supports smooth market entry.

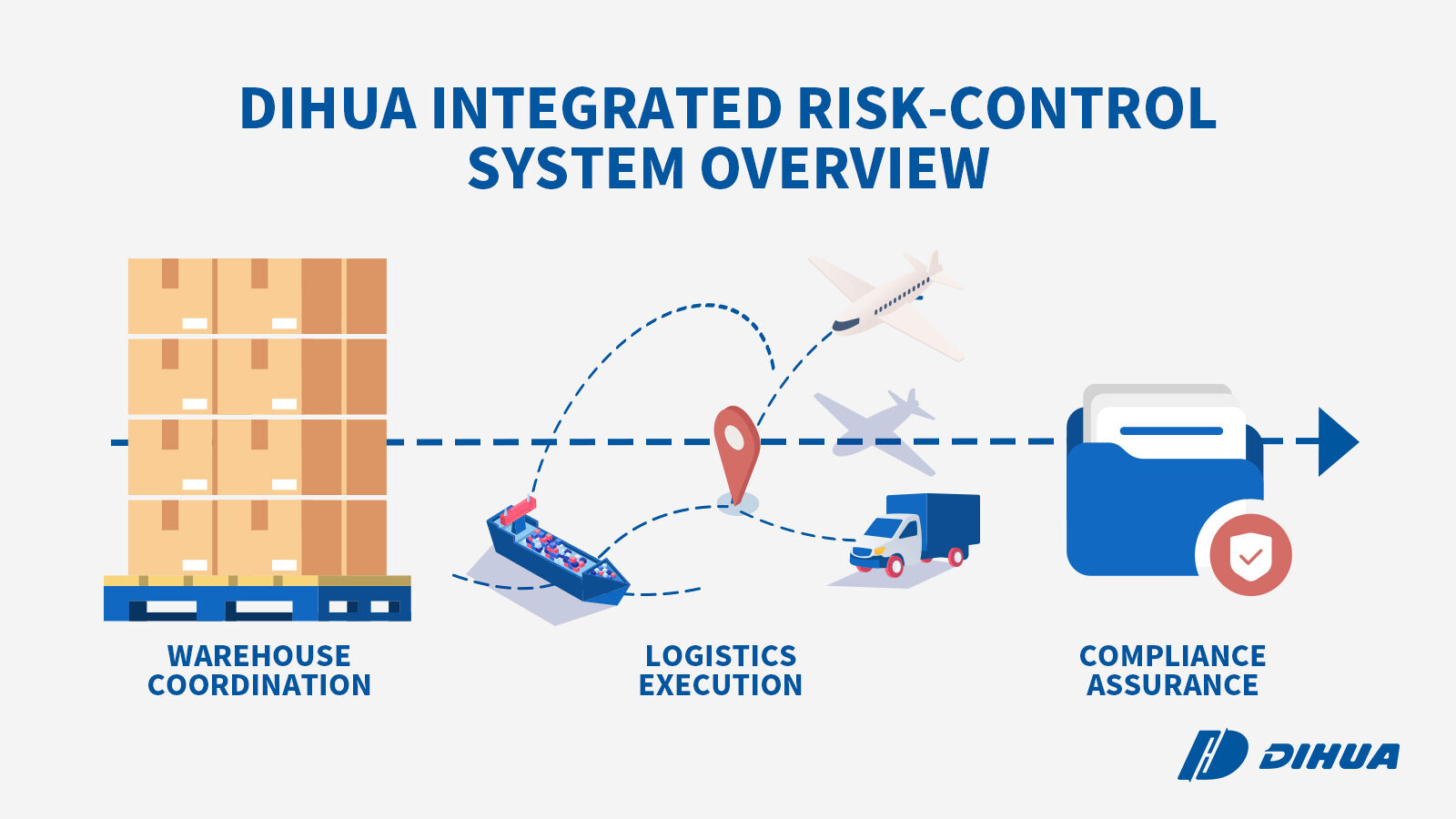

To meet this imperative, Dihua has built its system precisely around these needs, integrating warehouse coordination, logistics reliability, and full compliance documentation into one unified workflow. This structure reduces procurement uncertainty and helps customers maintain confidence across every stage of their sourcing cycle.

To reduce end-to-end procurement risks, Dihua integrates warehouse coordination, logistics execution, and regulatory compliance into one unified operational framework. This structure provides global buyers with consistent, predictable, and market-ready sourcing solutions.

· Warehouse Allocation & Multi-SKU Coordination

Dihua’s warehouse management system is optimized for the assortment-driven nature of the toy business. It supports:

· Mixed SKU consolidation, enabling buyers to combine multiple products into one shipment to reduce freight cost.

· Flexible partial or phased shipments that follow the buyer’s seasonal sales cycles.

· Inventory visibility and allocation planning to prevent overstocking or understocking.

This flexibility is particularly valuable for retailers and distributors who manage broad toy categories and require steady but not excessive replenishment.

· Delivery & Logistics Execution: Stable, Predictable, and Multi-Modal

To solve the industry-wide challenge of unpredictable shipping capacity, Dihua maintains a highly structured outbound system:

· Multiple shipping solutions including FCL, LCL, air freight, and railway cargo to meet diverse cost and time requirements.

· Reserved peak-season capacity to avoid the shipment delays and roll-overs that commonly occur from August to December.

· Planned loading schedules with transparent updates, allowing customers to align their inventory planning with promotional timelines.

· Complete export documentation, including BL, CI, PL, packing lists, and product-level carton breakdowns to ensure customs and internal audits proceed smoothly.

By ensuring structured outbound planning, multi-modal shipping options, and accurate documentation, Dihua significantly reduces one of the most critical risks for global toy buyers—delivery inconsistency that can disrupt launch timelines and market commitments.

· EU & U.S. Compliance Documents: Market-Ready and Audit-Ready

Dihua’s compliance support covers all essential international toy standards, including EN71, ASTM F963, CPSIA, EMC, and chemical-specific regulations. This end-to-end support delivers full documentation and traceability, encompassing:

· Full compliance documentation packages, including test reports, Declarations of Conformity (DoC), and labeling guidance.

· Regular updates aligned with evolving EU and U.S. regulatory requirements.

· Product safety file management to ensure every item is traceable and audit-ready.

For buyers entering marketplaces such as Amazon, Walmart, or major European retail chains, this support ensures that products pass their listing checks and regulatory reviews without delay — directly reducing administrative and legal risk.

Together, these capabilities create a unified risk-control framework that ensures stable supply, regulatory certainty, and market-ready execution for global buyers.

For global buyers navigating tight seasonal cycles and strict compliance environments, Dihua’s integrated system delivers measurable advantages:

· Lower operational uncertainty

Structured warehouse allocation, stable logistics and transparent documentation reduce unexpected disruptions across the supply chain.

· Faster speed-to-market

With complete compliance files and predictable outbound schedules, customers avoid delays that would impact retail launches or digital platform listings.

· Stronger supply stability

Dihua’s factory-trade model ensures both production execution and shipment fulfillment are aligned, preventing the common disconnect that occurs when manufacturing and trading are separated.

· Higher confidence in regulatory compliance

Buyers can list products in the EU and U.S. markets knowing the documentation meets the standards required by customs authorities, marketplaces, and corporate QA teams.

In short, Dihua enables customers to shift from risk-reactive procurement to risk-preventive sourcing, making their seasonal planning more accurate and their global expansion more secure.

As procurement risks continue to rise across the global toy industry, buyers need partners who can deliver more than product — they need delivery reliability, compliance assurance, and operational transparency. Dihua’s integrated warehouse, logistics, and safety-compliance system is built to provide exactly that: consistent supply, reduced sourcing risk, and the confidence required to enter demanding global markets.

With Dihua, buyers can move faster, plan earlier, and launch with certainty — supported by a sourcing partner engineered for today’s complex and fast-moving toy supply chain.

If you are preparing next season’s assortment or looking to strengthen supply-chain stability, our team is ready to support you.

Learn more at www.dihuatoys.com or meet our team in person:

· Hong Kong Toys & Games Fair 2026 — January 12–15, 2026

Contact Dihua to discuss your sourcing needs and secure a compliant, reliable, and risk-controlled supply foundation for your business.

Hot News

Hot News