Introduction

Each holiday season, global toy demand surges while logistics capacity tightens—pushing ocean spot rates sharply higher and compressing production schedules. In 2025, major container indices such as Drewry’s World Container Index (WCI) and the Freightos Baltic Index (FBX) reported steep, volatile increases on China–U.S. routes through November, highlighting sustained cost pressure across the trade. At the same time, Circana data showed toy sales rebounding in the first half of 2025 (global +7%, U.S. +6% through April), underscoring that disciplined, on-time delivery remains critical for capturing Q4 retail demand.

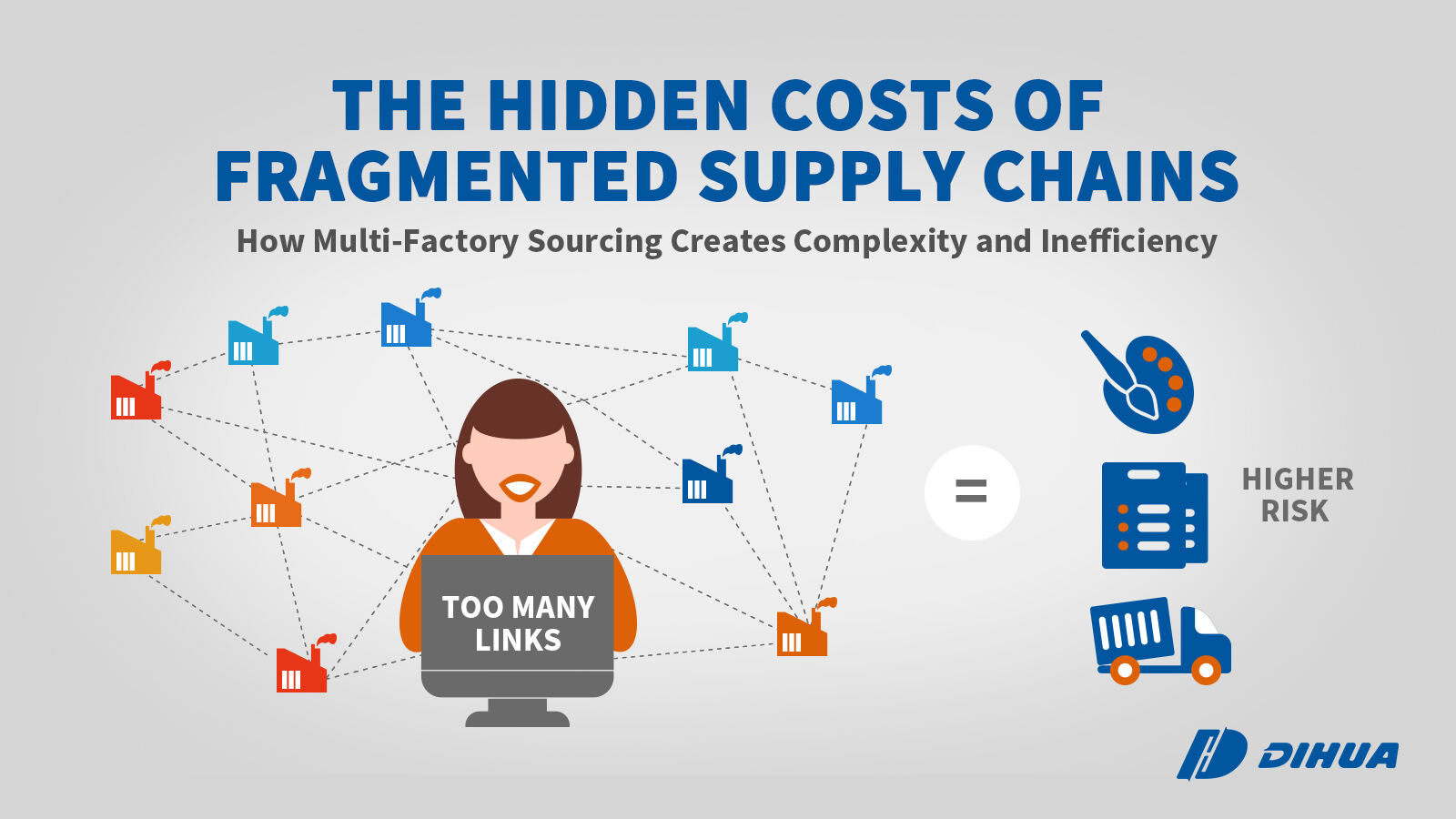

However, as volumes rise ahead of peak season, multi-factory sourcing and extended communication chains frequently create inefficiencies. Buyers coordinating several suppliers must manage inconsistent packaging standards, low cube utilization, and fragmented documentation—symptoms of “fragmented procurement” that slow execution and raise cost. These challenges reveal the hidden risks of a dispersed supply base and emphasize the need for an integrated toy supply chain that delivers greater efficiency, transparency, and control.

The Hidden Costs of Fragmented Supply Chains

For many overseas buyers, managing production through multiple factories and intermediaries has become the norm. Yet this structure often leads to fragmented procurement, where longer communication chains and scattered responsibilities result in inefficiency and higher operational risk.

· Too many factories, inconsistent execution: When orders are spread across several production sites, buyers face variations in color, printing, and packaging standards—differences that slow coordination and require costly rework to maintain consistency.

· Longer Links, low utilization: Lengthy coordination across factories and freight forwarders reduces container efficiency, often leading to under-filled shipments and increased logistics cost per CBM.

· Complex communication, weak documentation control: Multiple points of contact generate overlapping or missing paperwork—invoices, packing lists, and test reports—creating compliance risk and customs delays.

In essence, the more links in the chain, the less efficient the process becomes. To overcome these challenges, Dihua leverages its integrated Factory + Trade capability—combining in-house production capacity, multi-factory coordination, and strong R&D customization with full supply chain integration and one-stop delivery.

Dihua’s Integrated Factory + Trade Solution

As a trusted OEM/ODM and sourcing partner, Dihua merges factory precision with trading agility to create a truly integrated toy supply chain. This model gives global buyers end-to-end visibility, quality assurance, and delivery control — under one management system.

· One-Stop Capability: From R&D to Delivery

· Multi-Factory Synergy

With in-house production and a network of certified partner factories, Dihua runs unified operations across multiple sites. Centralized scheduling and real-time coordination ensure consistent quality, balanced capacity, and reliable lead times—even during peak seasons.

· In-House R&D and OEM/ODM Flexibility

Dihua’s R&D and engineering teams turn ideas into market-ready products through fast prototyping and customization. Our OEM/ODM flexibility supports tailored designs, packaging, and localization that meet global retail standards.

· End-to-end fulfillment

Through its Factory + Trade model, Dihua integrates production, inspection, and logistics into one seamless system. Optimized container loading, unified documentation, and centralized management provide buyers with transparent, cost-efficient delivery from start to finish.

· Compliance Advantage: Standardization & Testing Assurance

· Unified Production Standards

Dihua enforces standardized production and packaging across all partner factories—covering materials, color, printing, and labeling—to ensure consistent brand presentation and compliance in every shipment.

· Comprehensive Testing & Certification

All products meet ASTM F963, EN71, and CPSIA toy safety standards, supported by factories certified under BSCI、Sedex、ISO 9001/14001、ISO 22716 and U.S. GMP. A comprehensive testing and certification framework ensures product reliability and helps clients save valuable time when selecting a trusted sourcing partner.

· End-to-End Compliance Control

From raw materials to export documentation, Dihua maintains full compliance oversight through a centralized information system. Unified testing, certification, and reporting streamline approvals and reduce customs risk.

Delivering Efficiency, Stability, and Trust

By integrating production capability and trade coordination under one roof, Dihua delivers measurable value to global buyers through its Factory + Trade model:

· Consistent Quality: Standardized specifications eliminate color and packaging deviations across multiple factories.

· Higher Efficiency: Optimized container loading and synchronized production schedules reduce both time and logistics cost.

· Stable Delivery: Centralized oversight and unified documentation ensure consistent, on-time shipments —even in peak seasons.

· Reduced Risk: One accountable partner streamlines management and strengthens supply reliability.

In short, Dihua transforms fragmented sourcing into a transparent, performance-driven partnership, giving buyers full confidence in every order’s quality, compliance, and delivery. This dual strength—one-stop capability + full compliance control—gives international buyers a simpler, safer, and more efficient way to manage seasonal sourcing.

Evidence in Action: Proven Performance Across Global Projects

Dihua’s integrated Factory + Trade model is not just a concept—it has been validated through continuous delivery performance and long-term client partnerships worldwide.

· Proven One-Stop Efficiency

Between 2024 and 2025, Dihua achieved an on-time shipment rate exceeding 96% across more than 300 export orders, including large-scale Q3–Q4 programs for major U.S. and European retailers. Despite the freight congestion that marked late 2024, Dihua’s in-house logistics team effectively secured vessel space and prevented demurrage costs—demonstrating the reliability and agility of its integrated Factory + Trade model. Performance data derived from Dihua internal logistics and client project records (2024-2025).

· Certified Compliance Leadership

At Dihua, compliance is built into every step of our Factory + Trade model. All partner factories are BSCI、Sedex、ISO 9001/14001、ISO 22716 and U.S. GMP certified, and regularly audited to meet Walmart, Target, and Disney standards. Through a centralized production and documentation system, Dihua manages all EN 71, ASTM F963, and CPSIA testing to ensure every shipment meets global toy safety requirements.

This integrated workflow gives buyers full visibility of compliance and logistics data, minimizing re-testing and communication errors. Dihua also supports FSC and GRS certifications for sustainable materials, aligning with the EU Sustainable Product Regulation (2024) and ICTI 2024 findings that over 85% of European retailers now require verified ESG compliance.

By embedding certification control into its unified standards and container-level traceability, Dihua ensures safe, efficient, and transparent sourcing — the true strength of an integrated toy supply chain.

Preparing for the Next Peak Season

As peak seasons grow more complex, fragmented sourcing becomes less sustainable. The future belongs to integrated partners who can deliver both speed and compliance assurance.

Through its integrated toy supply chain, Dihua supports buyers with both flexibility and control: the ability to manage diverse SKUs while maintaining stable lead times and cost efficiency.

When cost and supply pressures rise, true advantage lies in simplifying complexity.Through Dihua’s Factory + Trade integrated model, buyers can reduce hidden costs, minimize coordination risks, and accelerate time-to-market.For importers and retailers, this means transforming seasonal uncertainty into strategic success — achieving sustainable growth through greater efficiency.

Call to Action

With its Factory + Trade model, Dihua provides a truly one-stop sourcing solution—combining multi-factory synergy, in-house R&D flexibility, and full compliance control from production to delivery. To secure reliable capacity and optimize your Q4 sourcing plan, connect with our team before the next production cycle begins.

Meet Us at:

Hot News

Hot News